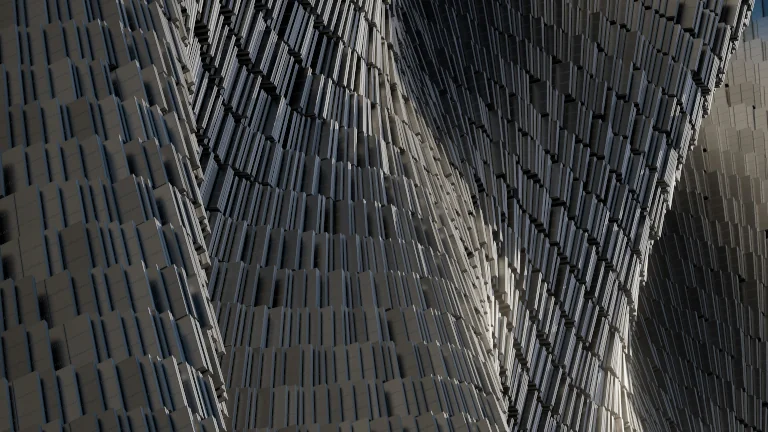

Aluminium Solid Panel Cladding in Sydney NSW

Aluminium solid panel cladding is a strong choice for modern facades where you want a clean finish, long service life and predictable maintenance. At SCE Corp we support aluminium solid panel cladding Sydney NSW projects for strata, owners corporations and commercial sites that need clear scope, documented quality checks and compliant outcomes. We start by confirming the existing wall build up, moisture risk and fixings then we recommend suitable panel thickness, coatings and detailing for corners, joints and penetrations. That early planning helps prevent water ingress, corrosion at fixings and premature surface wear. If you are replacing older cladding or upgrading for compliance, our team can coordinate access, staging and safety so the work stays organised from first site visit to handover.

Cladding Compliance and Installation Approach

Every site is different so we focus on practical decisions that match the building type and the project budget. For projects that begin with aluminium cladding North Shore Sydney inspections we review drawings, inspect the facade and record defects then we map out the highest risk areas first. We align the scope to relevant requirements and we document what will be repaired, replaced or upgraded so stakeholders can approve the plan with confidence. During installation we manage substrate preparation, fixings, flashings and sealants with routine hold points and photo records. That approach supports consistent finishes and helps keep warranty information and maintenance guidance clear for the building manager.

SCE Corp delivers aluminium solid panel cladding in Sydney NSW with documented QA checks plus clear scope from inspection to handover.

Benefits of Aluminium Solid Panel Cladding

Aluminium solid panel cladding is a strong choice for modern facades when you want a clean finish, long service life, and predictable maintenance. It offers high durability, stable performance in varied weather, and a sleek architectural look that suits both commercial and residential buildings. For property owners and strata managers, it can help reduce ongoing facade issues by supporting consistent detailing around joints, edges, and penetrations when installed correctly.

At SCE Corp, we approach aluminium solid panel cladding with a compliance and quality mindset. Our ISO 9001 quality systems support clear scope, documented checks, and consistent workmanship. Our ISO 14001 environmental systems guide responsible material handling and site practices. Our ISO 45001 safety systems support safe planning and delivery across active sites. As a DBP registered contractor, SCE Corp can also support projects where documentation and accountability matter, especially for remediation, upgrades, or staged replacement works.

If you are considering aluminium solid panel cladding in Sydney NSW, SCE Corp can help you choose practical options, confirm suitability for your building, and deliver a finish that is durable, compliant, and easy to maintain.

Frequently Asked Questions

1. What is aluminium solid panel cladding?

Aluminium solid panel cladding is a façade solution that uses solid aluminium panels to achieve a clean finish and predictable maintenance. It is often selected for upgrade and remediation scopes where consistent detailing and tidy presentation are important.

2. When is aluminium solid panel cladding a good option?

It is commonly considered when older cladding is deteriorating, when a façade needs a refreshed appearance, or when stakeholders want a robust system that can be detailed well at corners, joints, and penetrations.

3. What is included in aluminium cladding installation and upgrade work?

Scope typically includes inspection of existing conditions, confirmation of interfaces and fixings approach, access and staging planning, substrate preparation where required, installation, and documented quality checks through to handover.

4. What causes water ingress problems around aluminium cladding?

Water ingress is usually caused by failed joints, poor flashing details, penetrations, or incorrect sealing at interfaces. Good outcomes depend on correct detailing and disciplined installation checks, not only the panel selection.

5. How are fixings and corrosion risks managed?

Fixings approach is planned based on exposure and existing wall conditions. Corrosion risk is reduced by matching fixings and coatings to site conditions and by controlling moisture pathways through correct drainage and sealing details.

6. Can aluminium cladding be installed on an occupied building?

Often yes. Works are commonly staged by elevation or zones with controlled access, clear safety controls, and planned work windows to reduce disruption.

7. What is checked during an initial façade inspection?

Inspections typically review substrate condition, moisture risk points, existing defects, junction performance, and areas with visible movement or deterioration. Findings are then used to prioritise high risk sections first.

8. How is finish consistency maintained across a building?

Finish consistency comes from consistent panel layout planning, controlled installation tolerances, and routine checks at corners and junctions. Photo records and defined hold points help keep workmanship consistent from start to handover.

9. What documents are typically included in project closeout?

Closeout usually includes the agreed scope, photo records of key stages, product information available for the installed system, and documented checks aligned to the project requirements. This makes future maintenance decisions easier.

10. What details are needed for a quote in Sydney NSW?

A quote usually needs the address, height, access constraints, approximate façade area, and photos of the elevations and any defect areas. Call now to confirm the best next step.

Thank you for your visit and welcome to the construction home.